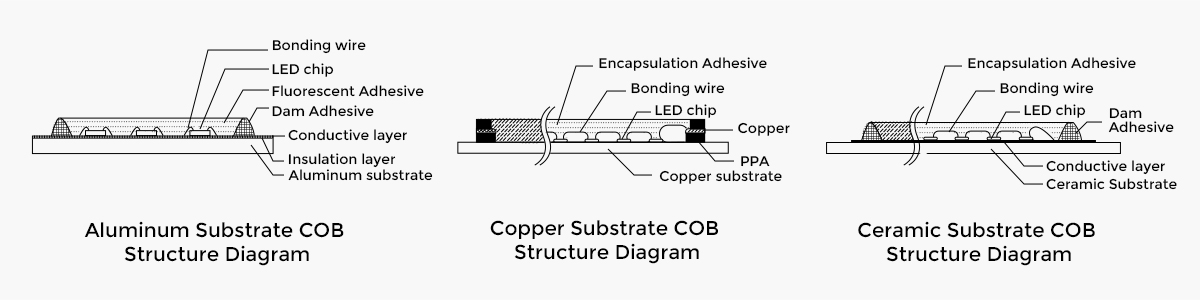

· Aluminum-based COB: Due to the low cost of aluminum substrates, aluminum-based COB offers an excellent cost-performance ratio, with a luminous efficiency of up to 130 LM/W. It is widely used in LED bulbs and downlights. However, due to the limited thermal conductivity of aluminum (1-2 W/m·K), it is suitable for 5-10W COB light sources.

· Copper-based COB: Copper's high thermal conductivity (380 W/m·K) allows it to be used for 20-50W COBs, with a luminous efficiency also reaching 130 LM/W. It is commonly used in LED floodlights and streetlights, though typically limited to 20-50W COBs to prevent localized overheating.

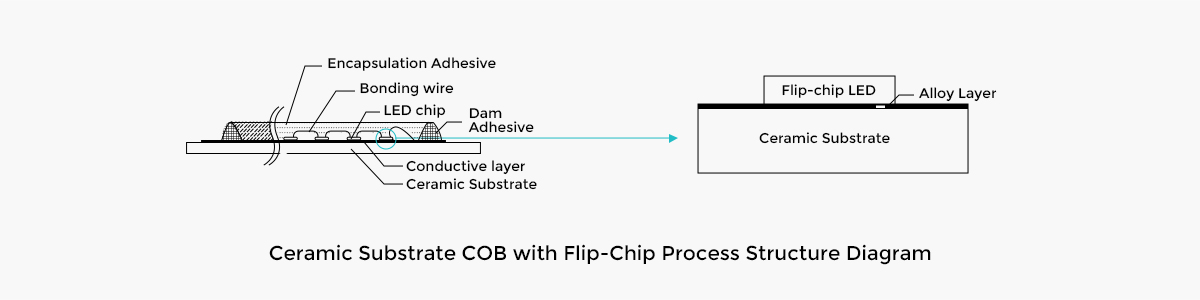

· Ceramic-based COB: Ceramic is recognized as the best material for LED packaging due to its superior thermal conductivity, insulation properties, and minimal thermal deformation. It is used in high-end, high-reliability LED lighting applications for 10-50W COBs. However, its higher cost restricts its use to premium LED lighting and high-reliability applications.

For specialized lighting applications requiring high reliability, such as LED street lights, tunnel lights, explosion-proof lights, and mining lights, the reliability of LED sources is crucial. Thermal effects, static electricity, and moisture are major reliability concerns.

Thermal effects are significant as they contribute to LED degradation. According to the Arrhenius model for LED chips, every 10°C increase in junction temperature halves the LED's lifespan. Ceramic substrates, with their high thermal conductivity and insulation properties, help address thermal and static electricity effects, while encapsulation technologies further enhance reliability.

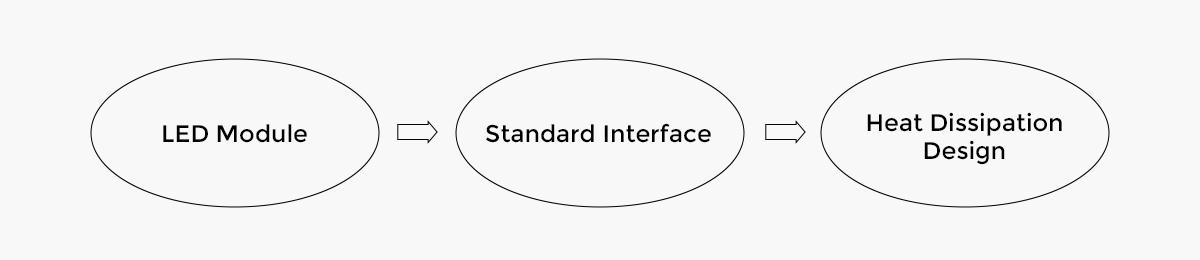

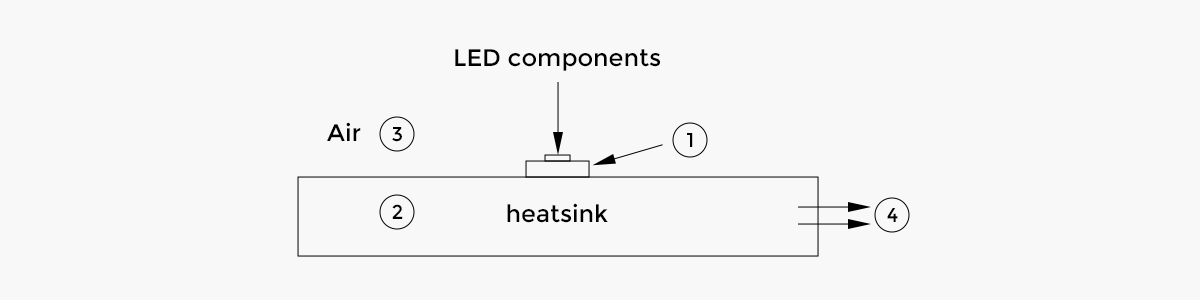

1. From the LED component to the heatsink.

2. Heat conduction through the heatsink.

3. Convection to the air.

4. Radiation through the surface.

1. The tightness and flatness of the contact surface between the LED component and the heatsink.

2. The total surface area of the heatsink.

3. The choice of heatsink material.

4. Optimization of fin design for gas flow.

LED packaging is a multidisciplinary field involving optics, thermodynamics, mechanics, electronics, materials science, and semiconductors. Effective LED packaging requires a deep understanding of thermal, optical, material, and process mechanics. LED packaging design should be integrated with chip design, considering light, heat, electrical, and structural performance. Integrating various components into LED modules will advance LED lighting technology more efficiently and rapidly.